Nelson's Wharf Restoration

When the land was acquired in 2013 it was in a very sorry state. The area had been overgrown with invasive scrub, the arm was covered with debris, mostly unrecognisable as a canal arm and the area had been used as an inert tip for years.

These are some of the Before and After images. Swipe left and right to see the changes.

Arm Restoration

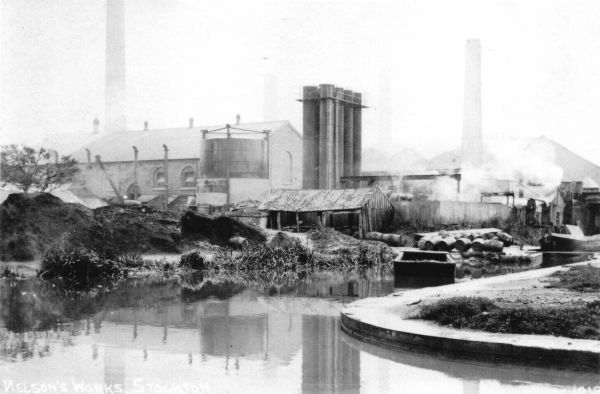

The land was made accessible again and the new Training Centre for Willow Wren Training was erected between October 2013 and March 2014. With that done, we set about restoring the canal arm which served the cement works from 1870 until its closure in 1949.

Scroll down to see the progress:

7th October 2015.

We have planning approval and once Rugby Ecology and Planning Office approve our ecology submissions we will start excavating in earnest. There are some 16,500 Cubic Meters of debris to remove to reveal the basin and it will take a lot of dumper runs to clear it all away. Fortunately, the soil is environmentally sound and we have room on other parts of the land to accommodate it.

At this stage we have little idea of what we will find. Our hope is that the canal infrastructure is still good and we will be able to repair the brick walling and reduce the need for modern steel piling. This is the first time for over 50 years that the basin has seen the light of day so we just don't know.

The first stage before we dig is to seal the arm off from the main canal and drain the water from the first part of the arm that we reinstated in 2014. The arm will now contain fish and the experts will be coming in to net them and return them to the main canal.

Rescuing the Fish

The arm is dammed off from the main canal the experts have netted all the fish to return them to the main line. The only exception to this were four Signal Crayfish which, as the law states, could not be set free.

Excavation Starts

All the boxes have now been ticked on the planning conditions so the big excavation begins. After  initially draining the arm, it soon filled up again from the land proving that the ground water has always been supplying the canal or it is running back in having been in water for sometime. Much later in the project we will need to prove the arm is leak proof as we did for this first section in 2014.

initially draining the arm, it soon filled up again from the land proving that the ground water has always been supplying the canal or it is running back in having been in water for sometime. Much later in the project we will need to prove the arm is leak proof as we did for this first section in 2014.

The next step is to start to reveal the bridge hole. With fingers crossed, the brickwork is still in one piece. The new footbridge won't need to rely on the integrity of the walls but it would be good if it all looked intact.

Progress 1

After just one day we can see the condition of the bridge hole sides.  It is amazing what one 25 tonne digger and two large dumpers can do. This is the first time these walls have seen daylight for around 60 years.

It is amazing what one 25 tonne digger and two large dumpers can do. This is the first time these walls have seen daylight for around 60 years.

If you look at the banner photo at the top of this page this view is looking from the left side of the bridge hole toward the right side. This is where the footbridge will span.

The Staffordshire blue bricks are in excellent condition and apart from a little pointing at a later date the walls are perfect. Some of the wall further to the left will be left as it is to allow bats to roost.

This has only been excavated to towpath level, we will start digging to the bed after we have made a few repairs to the wall coping on the nearside.

Progress 2

Before digging to canal bed level we had to do some minor repairs to the bridge wall coping. The original rail bridge walls won't be used to support the new footbridge but the coping will be difficult to get to when the new bridge is in place.

Before digging to canal bed level we had to do some minor repairs to the bridge wall coping. The original rail bridge walls won't be used to support the new footbridge but the coping will be difficult to get to when the new bridge is in place.

The gritstone blocks were in remarkable condition and only needed relocating and cementing into place.

After the repairs to the coping were complete we were able to start excavating down to canal bed level. At this stage we had no idea of what had been dumped in the arm or in what condition the canal walls were in.

Luckily the first 10m or so revealed the walls to be in great condition especially the right hand side which was the horse towpath side.

Tomorrow we need to go further down the arm but we need to hurry up as the new footbridge is scheduled to arrive soon.

Progress 3

Great progress again today despite the weather. A mixture of soil, concrete, bricks and metal has been coming out of the infill. The soil is going to another area of our land which needs building up, the metal is being sold on and the bricks and concrete will be crushed on site to make the access roads.

Great progress again today despite the weather. A mixture of soil, concrete, bricks and metal has been coming out of the infill. The soil is going to another area of our land which needs building up, the metal is being sold on and the bricks and concrete will be crushed on site to make the access roads.

The walls of the arm are really looking good. We will have to make repairs but thanks to the years of being filled in they have been protected to a great extent.

Ground water continues to run into and stay in the arm which is a good sign. The clay bed is in great condition.

That's enough excavating for this week. We are now ready for the bridge to be installed!

Progress 4 - The Bridge Arrives

We reached another milestone in Nelson's History today with the arrival and installation of the new footbridge to span the arm.

We reached another milestone in Nelson's History today with the arrival and installation of the new footbridge to span the arm.

The original bridge carried the L&NWR railway between Leamington Spa and Weedon which was a casualty of the Beeching cuts.

The original bridge carried the L&NWR railway between Leamington Spa and Weedon which was a casualty of the Beeching cuts.

When the cement works was demolished, the debris was used to fill the arm and eventually a footpath was formed over the top. The new bridge carries this footpath.

The new bridge carries this footpath.

It took only a couple of hours to fit the mounting blocks and then lift the bridge into position. It was then fixed in position before we made it safe to use.

Progress 5th November 2015.

Progress has been slowed by the weather somewhat this week and we have had the odd mechanical breakdown. On Monday we couldn't see our hand in front of our face, the digger refused to start on Tuesday and one of the dumpers had a puncture.

Progress has been slowed by the weather somewhat this week and we have had the odd mechanical breakdown. On Monday we couldn't see our hand in front of our face, the digger refused to start on Tuesday and one of the dumpers had a puncture.

We have been working the kit hard over the past few weeks so it isn't surprising that it all needs a day off.

It is raining today and making things a tad messy. The weather is only going to get worse over the next few weeks and we might have to put a halt to digging and concentrate on repairing the brick basin walls exposed to date.

It is raining today and making things a tad messy. The weather is only going to get worse over the next few weeks and we might have to put a halt to digging and concentrate on repairing the brick basin walls exposed to date.

Despite the minor setbacks, we have managed to do a little landscaping on the sides of the basin and while we were doing it we found some more brickwork and a kiln arch.

We are going to do our best to retain what we can of the kiln. It is difficult to see from the photo just where it is but we know it will be right by the side of the canal arm.

It really is difficult to describe how exciting it is to be uncovering history in this way. These structures haven't been in use for 65 years and haven't been seen for the last 50 years plus. We are finding some interesting artefacts like these old narrow gauge railway wheels too. Is this the humble beginning of the "Nelson's Wharf Light Railway"?

Progress 10th November 2015.

After such great progress over the past few weeks we have stalled a little. The wheels have fallen off our wagon, or to be more precise, the track came off the excavator. We are now waiting for spares to come before we can refit the track and get back on digging out the arm.

After such great progress over the past few weeks we have stalled a little. The wheels have fallen off our wagon, or to be more precise, the track came off the excavator. We are now waiting for spares to come before we can refit the track and get back on digging out the arm.

Before it happened we managed to do more landscaping and to open up more of the side of the arm revealing what we know is a line of several lime kilns. It is wonderful to see structures that have been buried for decades when very little else was left standing after the demolition in the mid-sixties.

Before it happened we managed to do more landscaping and to open up more of the side of the arm revealing what we know is a line of several lime kilns. It is wonderful to see structures that have been buried for decades when very little else was left standing after the demolition in the mid-sixties.

Time is never really lost so we can still get on with lighter clearing up, landscaping and fencing in between bouts of bad weather. Our workers are made of stern stuff.

Progress 12th November 2015.

Digger back in action and with two dumpers running none stop the progress is rapid. First we found one kiln now we have three.

Digger back in action and with two dumpers running none stop the progress is rapid. First we found one kiln now we have three.

If the map from 1905 is correct we should have eight kilns in total on the north side of the arm and more on the south side.

The bottom of all the kilns should be above the tow path level and set back slightly so the produced lime could be drawn out of the bottom of the kiln and into the boats for transport. All these brick kilns were eventually superseded by the higher capacity rotary kilns. Will try to find out when these kilns were last used.

Progress 19th November 2015

It is a slow process digging thousands of cubic metres of debris and if you see it every day then sometimes you don't appreciate the great progress that is being made. We are finding soil, concrete, bricks and a lot of scrap metal and it all needs digging up, sorting and then dumping in the right place.

It is a slow process digging thousands of cubic metres of debris and if you see it every day then sometimes you don't appreciate the great progress that is being made. We are finding soil, concrete, bricks and a lot of scrap metal and it all needs digging up, sorting and then dumping in the right place.

The soil is going to fill up a hollow on our land thank goodness. If we had to pay for disposal it would have killed the project. The concrete and bricks are being piled up ready for crushing to give us all the hardcore we will need for roads etc. The scrap metal will be sold on despite the current low price.

The soil is going to fill up a hollow on our land thank goodness. If we had to pay for disposal it would have killed the project. The concrete and bricks are being piled up ready for crushing to give us all the hardcore we will need for roads etc. The scrap metal will be sold on despite the current low price.

The main aim is to dig out the old arm but in doing so we are now seeing more of the line of kilns that exist along the side of the arm. So far we have found three but there should be eight or nine. We thought they would all have been demolished but they are in good condition considering they have been buried for at least 50 years. We might still have to take down parts of the tops to make them safe but with a bit of brick repair we should be able to save the main structure of most of them.

The main aim is to dig out the old arm but in doing so we are now seeing more of the line of kilns that exist along the side of the arm. So far we have found three but there should be eight or nine. We thought they would all have been demolished but they are in good condition considering they have been buried for at least 50 years. We might still have to take down parts of the tops to make them safe but with a bit of brick repair we should be able to save the main structure of most of them.

We are also seeing lots of artefacts. We now have five pairs of narrow-gauge wheels. These were part of the internal railway tipping trucks that were used to bring limestone up to the kilns pulled either by horse or steam locomotive. The works had its own blacksmith shop and an unknown quantity of horses.

Progress 23rd November 2015

The depth of the infill is now very deep and in order to progress just a few meters a day we are having to move a lot more debris. The only way to achieve that is to dig down in layers so the excavator can still reach the layer below. So progress per linear meter is slower but the amount of infill being removed stays the same with two dumpers going flat out.

The depth of the infill is now very deep and in order to progress just a few meters a day we are having to move a lot more debris. The only way to achieve that is to dig down in layers so the excavator can still reach the layer below. So progress per linear meter is slower but the amount of infill being removed stays the same with two dumpers going flat out.

We had a bit of spare time on Friday so we sent the drone up to check on progress from overhead. The top photo shows the main Grand Union in the background with the arm running diagonally. The part between the canal and the new bridge was recovered in 2014, the section between the bridge and bottom left of the picture was done in the last few weeks.

The bottom photo shows the arm running from the bottom right corner to the middle. The area on the left has been nicknamed the Somme since it started getting soaked.

Progress 10th December 2015

Progress has been somewhat slow recently due to the bad weather and we have spent a lot of time just consolidating what we have done to date. The weather itself is fine, we have all weather kit and all weather workers but the ground is sodden and we are carrying mud everywhere. This is a problem where we have to go across the training centre access road.

Progress has been somewhat slow recently due to the bad weather and we have spent a lot of time just consolidating what we have done to date. The weather itself is fine, we have all weather kit and all weather workers but the ground is sodden and we are carrying mud everywhere. This is a problem where we have to go across the training centre access road.

Still, that gave us more time to properly clean up the kilns. One is bricked up but the other two are open with ash still in the fire hole. The flat area in the foreground is the towpath of the canal arm and it is in good condition.

Still, that gave us more time to properly clean up the kilns. One is bricked up but the other two are open with ash still in the fire hole. The flat area in the foreground is the towpath of the canal arm and it is in good condition.

We now have even more pairs of wheels, all we need now is a wagon to put them on.

One more photo of one of the kilns. They are great pieces of history.

Progress 22nd December 2015

The ground is still a bit wet to be driving dumpers over and since we have a new starter at Nelson's, a bricklayer, it is time to start repairing the walls and structures.

The ground is still a bit wet to be driving dumpers over and since we have a new starter at Nelson's, a bricklayer, it is time to start repairing the walls and structures.

The corner had completely fallen away and it needed rebuilding so the adjoining wall had some support. Fortunately, we have  thousands of bricks to use that came from the demolished works so it is a fairly economically build.

thousands of bricks to use that came from the demolished works so it is a fairly economically build.

In parallel, we need to repair some of the canal wall footings that had fallen away when we took out the debris. Quite a bit of canal arm wall had fallen into the canal where there wasn't debris holding it up and we didn't want the same fate to come to this section.

Armed with 50 hessian sandbags and dry concrete we set about underpinning the wall. The filled sandbags were driven into the crevice under the wall to give the concrete beam above it some support. Only time will tell if this was a good plan but it is far better than demolishing the wall and replacing with steel piling.

The workers want to carry on over Christmas so providing the weather is fairly dry we should see some more progress by the first week of January.

Progress 14th January 2016

If you hadn't noticed, December was the wettest for a very long time and it hasn't dried up since. So the earth movement is on hold for the foreseeable future. The good news is that the bricklayer from the village can remain working with us and we are starting to repair the walls that we have exposed so far.

If you hadn't noticed, December was the wettest for a very long time and it hasn't dried up since. So the earth movement is on hold for the foreseeable future. The good news is that the bricklayer from the village can remain working with us and we are starting to repair the walls that we have exposed so far.

Back to Christmas, we didn't run the pump over the holiday and the rain was so heavy that the basin filled up almost the same as the canal level. If we had left it one more day it would have been level. No water is getting past our clay dam from the main canal it is all coming from ground water. That is good news when we come to do the leakage test just before we reopen the basin to the main line.

Before we start to repair the basin walls we needed a safe and comfortable way of positioning the bricklayer. We had tried draining the basin and using pallets. This worked but it was never  just the right height and didn't offer much protection from the elements. Brickies like to be dry. They say its just for the mortar but we aren't sure.

just the right height and didn't offer much protection from the elements. Brickies like to be dry. They say its just for the mortar but we aren't sure.

By coincidence, someone was selling an unpowered "butty" on eBay and we snapped it up. At 17ft long and 5ft wide with an open hold it has proven to be ideal especially when we put a frame and tarpaulins over the top. The bricky can work in relative comfort and we can adjust the water level to help him work at the ideal height.

Progress 27th January 2016

The weather is still holding up the clearance of debris from the arm but there is nothing we can do  about the ground. So we are concentrating on rebuilding the walls exposed to date.

about the ground. So we are concentrating on rebuilding the walls exposed to date.

The butty is proving to be a godsend and is perfect for doing this job. We can adjust the working height by draining the arm or allowing it to fill overnight. When we need a really stable platform we let the boat sit on the bottom.

When we recovered the first part of the arm in 2013, the wall had already fallen into the water and broken up. We couldn't rebuild it so we had to revert to steel piling.

When we recovered the first part of the arm in 2013, the wall had already fallen into the water and broken up. We couldn't rebuild it so we had to revert to steel piling.

We now need to extend the piling into the corner before building a returning wall and while we are there we are going to build in a set of safety steps. Ladders are more compact but if an animal was to fall in then they aren't much good at climbing.

Progress 19th April 2016

Apologies to those of you who monitor this page for news. If we had realised how many were looking forward to our next instalment we would have kept it more up to date.

Apologies to those of you who monitor this page for news. If we had realised how many were looking forward to our next instalment we would have kept it more up to date.

Progress with digging out the basin has been slow and we haven't moved any further into the land. Except for a week last month, the ground conditions have prevented us moving earth so no progress has been made on excavating the arm. However, we have had the services of a bricklayer or two and have been busy repairing the walls and setting concrete capping in place. The photo on the right shows the repaired wall with the first section of shuttering in place after the first pour of concrete has been made.

After a few weeks we are up to the stage where the third concrete slab has been formed and we are about to put the shuttering in place ready for the fourth. It takes a few days with each one to allow for the concrete to dry before removing the shuttering and moving it on to the next section. Notice the new escape steps on the right of the photo.

After a few weeks we are up to the stage where the third concrete slab has been formed and we are about to put the shuttering in place ready for the fourth. It takes a few days with each one to allow for the concrete to dry before removing the shuttering and moving it on to the next section. Notice the new escape steps on the right of the photo.

The "butty" has been very useful. On the wet days, it still allows us to lay bricks in the rain by using the makeshift canopy. It also keeps the bricklayer happy although we stopped short of allowing him to fit a stove in the boat!

Progress though is much faster when the rain holds off and we can go back to using pallets and scaffolding planks. It even allows us to use more than one bricklayer while having a third person mixing the mortar and putting the bricks within arms reach.

We have had to use some modern engineering bricks at the core of the wall which allows us to ration out the genuine bricks for the outer face. We are rescuing as many of the original bricks as we can but quite a few have been lost when trying to clean off the old mortar.

The side where most of the work is being carried out wasn't actually the towing path side of the arm. Just beyond the bridge supports, the brickwork of the arm was actually the walls of a steam driven power station. So we are repairing the wall then fitting a concrete coping which is the same level as a long block of concrete which was on the inside of the building.

The original towpath was on the left hand side of the arm as viewed toward the main canal but we want to use the right hand side, as seen in this photo, for moorings as the access to this side will be much better for moorers.

The original towpath was on the left hand side of the arm as viewed toward the main canal but we want to use the right hand side, as seen in this photo, for moorings as the access to this side will be much better for moorers.

Not wanting to let the digger driver go we have kept him busy "peckering" the concrete base next to the arm and digging it up ready for the crusher to convert it to the much needed hardcore. Our aim with the project has always been to restrict what comes in and what goes out with a preference to recycling rather than replacing. The next step for this area will be to cover the clay and then add a hardcore layer. We won't put the top layer on for sometime yet.

We have however had our first major setback. After some very heavy rain earlier this month we lost one of the walls on the original part of the basin, i.e. nearer the main canal. We weren't totally convinced of its stability especially since the one opposite had fallen in well before we bought the land.

We have however had our first major setback. After some very heavy rain earlier this month we lost one of the walls on the original part of the basin, i.e. nearer the main canal. We weren't totally convinced of its stability especially since the one opposite had fallen in well before we bought the land.

What started off as a 50mm crack in the ground first thing in the morning gradually became 400mm by the middle of the day. It didn't actually fall in the arm but it was close enough that we had to remove it. The photo on the right shows a bend in the wall that should be straight.

When we dug it out, we found it had been laid on clay and was devoid of any firm foundation. On the bright side, at least it fell in now and not when we had several boats in the basin.

We are now getting quotes for replacing the wall with a brick structure or installing heavier duty steel piling with concrete capping. At the moment, the latter is favoured. It isn't as authentic but it will be more durable in an area where we need strength.

Progress 1st June 2016

When we removed the remaining brick walling we discovered it had been laid on clay.

When we removed the remaining brick walling we discovered it had been laid on clay.

That made the comparison of pricing to replace like for like or to fit steel piling much easier. By the time we have laid new footings and rebuilt the wall we could have installed far more robust steel piling.

In the end we chose GJP Marina Developments to fit the steel piling. We also decided to repair the stop plank grooves which had never been as good as we would have liked them to be.

This was going to dig deep into the budget but the integrity of the basin is paramount and we need to get the "front door" right.

The new stop plank groove structure begins to take shape. After digging deep, installing piles below the structure, the shuttering was installed and the concrete was poured.

The new stop plank groove structure begins to take shape. After digging deep, installing piles below the structure, the shuttering was installed and the concrete was poured.

Once that had dried sufficiently, the shuttering for the uprights were assembled and more concrete poured.

Before you know it, we have a new stop plank structure.

Very soon after, it is blended in with the existing piling/brickwork and we have a restored entrance to the basin.

The plan going forward is to install the steel piling to replace the brick structure which started all this off as well as continuing the wall restoration on the rest of the basin.

The brickwork for Stage 1 is now completely finished but we have a lot of concrete to pour to create the coping. To do that we need to improve the access to the canal side for the concrete mixer. We have planning approval for all of that so as soon as we crush some more concrete we will be on the case.

We did have one major setback similar to the basin wall.  After a great deal of heavy rain, we arrived at work to find a pile of bricks below one of the kilns. We were always suspicious of the structure and had been monitoring movement but the walls were moving a lot and beginning to collapse.

After a great deal of heavy rain, we arrived at work to find a pile of bricks below one of the kilns. We were always suspicious of the structure and had been monitoring movement but the walls were moving a lot and beginning to collapse.

In the end, to keep everyone safe we have had to demolish the kilns from the top down. We will now just retain the bottom metre or so to show where the structures were for heritage instead of turning them into what would have been great bat caves.

Such a shame but they were simply too dangerous to keep and being so close to the edge of the basin, it was too complex to shore up.

Progress 12th July 2016

Stage One of the basin restoration is now almost complete. All the walls have been repaired and we only have a few sections of concrete coping to install.

Since we completed the replacement stop planks and removed the clay bunds, (one blocking off the arm and one between the stop planks and the main line), the arm has been gradually filling with rain water. It therefore made sense to start the leakage, or stilling test. The water was lapping at the stop planks and we were spending a lot of man-hours keeping them watertight with fly ash.

Since we completed the replacement stop planks and removed the clay bunds, (one blocking off the arm and one between the stop planks and the main line), the arm has been gradually filling with rain water. It therefore made sense to start the leakage, or stilling test. The water was lapping at the stop planks and we were spending a lot of man-hours keeping them watertight with fly ash.

For those of you who haven't seen it, fly ash is superb at stopping leaks. No matter how good the stop planks have been made, there are always gaps and the water, under a fair amount of pressure, will force its way through. If you treat the leaks with fly ash by carefully placing it with a spade under water near the leak it will seal up the gap. It isn't permanent and is easily disturbed by boat wash for example so it needs to be reapplied regularly.

We then carried out the stilling test by monitoring the water level in the basin, noting weather especially rainfall, sun, wind. The idea is that the water level shouldn't change more than would be expected by the effects of the weather. The basin passed the test with flying colours and whilst the main line varied greatly from use of the locks, the basin stayed within a very narrow margin. The result was that CRT, after being inspected by their Engineer, allowed us to stop the monitoring, allow the ash to fall away and let the basin find the same level as the main line.

We then carried out the stilling test by monitoring the water level in the basin, noting weather especially rainfall, sun, wind. The idea is that the water level shouldn't change more than would be expected by the effects of the weather. The basin passed the test with flying colours and whilst the main line varied greatly from use of the locks, the basin stayed within a very narrow margin. The result was that CRT, after being inspected by their Engineer, allowed us to stop the monitoring, allow the ash to fall away and let the basin find the same level as the main line.

We were pleased with this because we had two incidents with wildlife falling into the void. A grass snake, after a lot of patient waiting, cleverly managed to find its way out, (see You Tube https://youtu.be/0V9rcrpCVJ8) but sadly a duckling didn't. CRT have asked us to leave the stop planks in place until the review meeting we have with them next week.

We were pleased with this because we had two incidents with wildlife falling into the void. A grass snake, after a lot of patient waiting, cleverly managed to find its way out, (see You Tube https://youtu.be/0V9rcrpCVJ8) but sadly a duckling didn't. CRT have asked us to leave the stop planks in place until the review meeting we have with them next week.

Soon after that, we will be taking the first boat into the basin proper for probably around 50 years. We have had boats into this first section but never under the bridge.

Progress November 2016

It is a long time since we updated the restoration.  There was a wait until CRT approved final removal of the stop planks, we then had an informal boat gathering to celebrate four birthdays. The gathering in September also served to recognise the opening of Stage One of the basin restoration.

There was a wait until CRT approved final removal of the stop planks, we then had an informal boat gathering to celebrate four birthdays. The gathering in September also served to recognise the opening of Stage One of the basin restoration.

The work to restore Stage Two goes on but progress is slowed because of the weather.

We still have tonnes of debris to remove and walls to repair before we can start connecting the moorings with water and power and welcoming in moorers. We now have a long list of interested people and will be contacting them soon with prices and conditions.

We still have tonnes of debris to remove and walls to repair before we can start connecting the moorings with water and power and welcoming in moorers. We now have a long list of interested people and will be contacting them soon with prices and conditions.

Fingers crossed for good weather and hard ground conditions so we can get on with the restoration.

February 2017

The winter wasn't very kind and the ground work pretty much stopped from November through until late February.  Fortunately we have a good contract with the plant supplier and very flexible workforce which meant we weren't out of pocket too much.

Fortunately we have a good contract with the plant supplier and very flexible workforce which meant we weren't out of pocket too much.

Although we had planning permission for a sliding bridge across the narrowing of the arm, we had decided that a lift bridge would be much better. We needed to go back to planning to get approval which of course meant a completely new application.

Although we had planning permission for a sliding bridge across the narrowing of the arm, we had decided that a lift bridge would be much better. We needed to go back to planning to get approval which of course meant a completely new application.

We got the approval so one thing we could get on was the footings for the new structure. That was followed by an inordinate amount of concrete for mass ballast followed by a "cast on site" block complete with mounting bolts for the bridge.

Nobody said restoring a canal arm was going to be cheap.

March 2017

As the weather got better and ground conditions improved we started moving tonnes and tonnes of material. At one point we had one 20 tonne excavator and two 6 tonne dumpers going flat out.

As the weather got better and ground conditions improved we started moving tonnes and tonnes of material. At one point we had one 20 tonne excavator and two 6 tonne dumpers going flat out.

It wasn't long before we got much deeper into the arm. We found a fair few artefacts but none as big as the fore end and stern of a Joey boat. Some of the locals had said there used to be an open boat which they used to carry cement from one end of the arm to the other and we suspected it might be buried here somewhere. Sadly, when the factory was demolished the boat was crushed and it came up in pieces of iron and elm . We have kept as much as we could salvage and will be doing something with it all at a later date.

As well as the Joey, we uncovered even more kilns and structures. It might only be the bases of the kilns but we will make them safe and keep them on show.

As well as the Joey, we uncovered even more kilns and structures. It might only be the bases of the kilns but we will make them safe and keep them on show.

At long last we reached the long lost end of the Nelson's Cement Works Basin. Until now we didn't know how it ended because the maps were unclear in what was canal structure and what was the over hanging buildings.

At long last we reached the long lost end of the Nelson's Cement Works Basin. Until now we didn't know how it ended because the maps were unclear in what was canal structure and what was the over hanging buildings.

But here it is, just a blank wall.... Believe it or not, the whole team saw this as a historic moment in the restoration and it should be borne in mind that this was the first time this ground had seen the light of day for around 50 years plus.

We actually have planning approval to open out the arm for a winding and install a slipway but we are going to put those plans on hold so we preserve the original structure.

April 2017

Now the main excavation is done we can start to shape the rest of the basin. Once again, with a 20 tonne excavator, good dumper and great operators it soon started to take shape. We had good days and bad days but with other work to do around the site we kept everybody busy.

Now the main excavation is done we can start to shape the rest of the basin. Once again, with a 20 tonne excavator, good dumper and great operators it soon started to take shape. We had good days and bad days but with other work to do around the site we kept everybody busy.

The groundwork is one thing but it would be a few more months before all the brickwork could be repaired and concrete coping poured. We had two full time brickies working on the walls as well as bringing in sub contractors as required.

We decided to set a target of completion for the end of July 2017!

14th August 2017

We went away for summer holiday and when we came back at the end of the first week of August we were treated to this view:

We went away for summer holiday and when we came back at the end of the first week of August we were treated to this view:

The basin sides have been shaped, top soil spread and car park laid to create the basin shape we wanted. It isn't as it was originally because the cement works surrounded the arm but the arm itself is as original as possible and the landscaping has created a wonderful view. It's going to be a really nice place to moor.

In parallel, all the brickwork repairs had been completed and the last bits of concrete were poured just after we got back. Once dry, the shuttering will be removed and we can refill the arm ready for the leak, (stilling), test.

It wasn't part of the restoration, but we decided we needed a bridge across the narrowing to get regular access to the other side of the arm. The bridge was erected long before we went on holiday but there were problems and only now has it finally been commissioned.

It wasn't part of the restoration, but we decided we needed a bridge across the narrowing to get regular access to the other side of the arm. The bridge was erected long before we went on holiday but there were problems and only now has it finally been commissioned.

All being well, providing the leak test is okay, the arm will be fully open in a couple of weeks time, (early September). At that point, we will be addressing our list of interested moorers to see who is ready to come or to pay a deposit to come.

September 2017

The arm is now fully open and we already have narrowboats moored in the arm with more to follow. It has taken two years to restore but we are there now and we can enjoy the heritage of a canal arm first built in 1870.